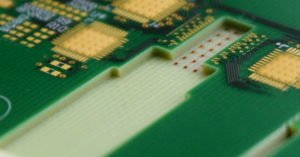

Blind milling on a printed circuit board design is used for several reasons.

For example:

1. To be able to create component openings or cut outs.

2. Plated blind milling is used for heat removal.

3. To be able to fix special profiles.

In the case of blind milling, the parameters of the usual mill are applicable.

At Brandner the tool size for blind milling ranges from 0,6mm to 2,5mm.

The depth tolerance for blind milling is +/- 7µm.

In the gerbers, please provide the following:

– Outline and milling path.

– Separate layer for the blind milling that is marked clearly.

– The depth of the milling (in mm-s).

– Is the blind milling plated or not.