Back drilling is a handy way to achieve an electrical connection between the inner and outer layers of the printed circuit board when the drill aspect ratio is not sufficient for drilling blind vias.

The manufacturing goes as follows – first we drill through the board as for normal plated through hole (PTH) and process it in pre-plating solution to prepare the hole for metallization. Then the holes are re-drilled to partially remove the pre-plating substance. This ensures that later in the plating process the metal only adheres to this pre-determined depth of the via where pre-plating is still intact.

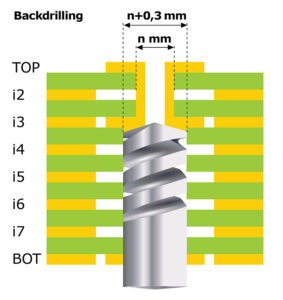

The penetration of various solutions in through vias is significantly more effective compared to blind vias, hence the plating result will also be better. If back drilling is considered, please bear in mind that the drill size for back drilling has to be at least 0,3 mm larger than for the initial PTH and the minimal clearance from the back drilled holes is 0,2 mm. If in doubt, err to the bigger side or consult with our sales assistants at sales@brandner.ee.